- +91 96111 97599

- info@taaayanam.com

- Bengaluru, Karnataka INDIA 560 094.

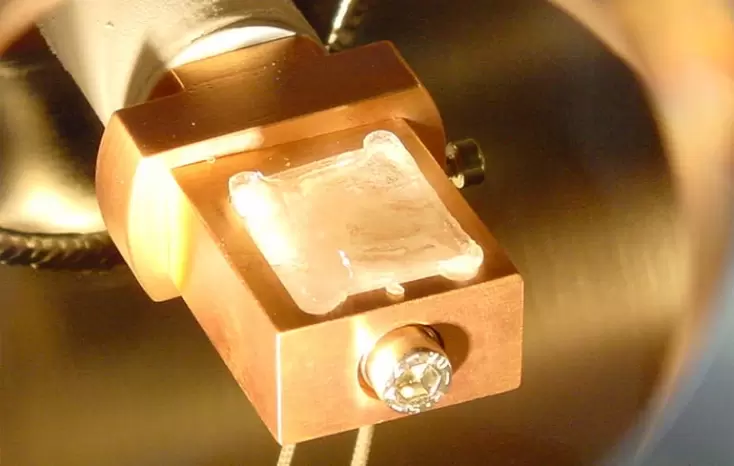

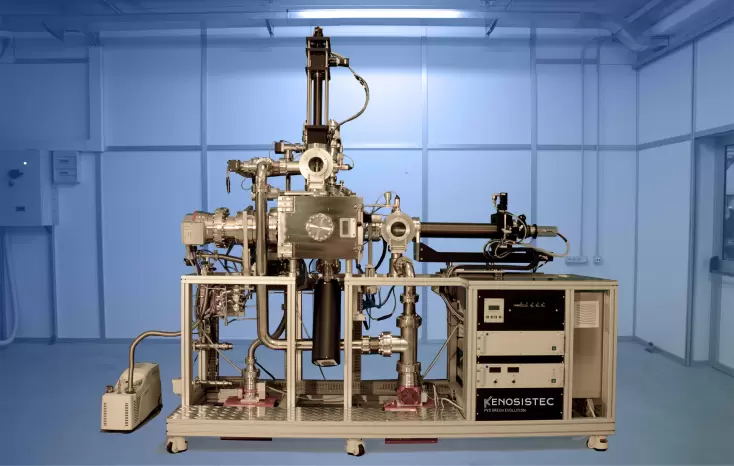

PLD involves the use of a high-energy laser to ablate (vaporize) a target material in a vacuum or controlled atmosphere. The ablated material is then deposited onto a substrate placed opposite the target. The laser ablation process generates a plasma plume composed of ions, atoms, and clusters of the target material, which condenses onto the substrate to form a thin film.

The PLD technique offers numerous advantages.

The most important are:

WhatsApp us